A Guide to Different Types of Screws

Screws are a very common tool, typically used as fasteners to join pieces and materials together. However, choosing the kind of screw will be an important decision. By using the right kind of screw you’re not only protecting the materials you’re working with, but you’re also ensuring that securely drilling the screw will remain both an easy and safe endeavor.

5-Minute Crafts has prepared a guide to provide information on the different types of screw drives, as well as examples of recommended screws for different surface materials.

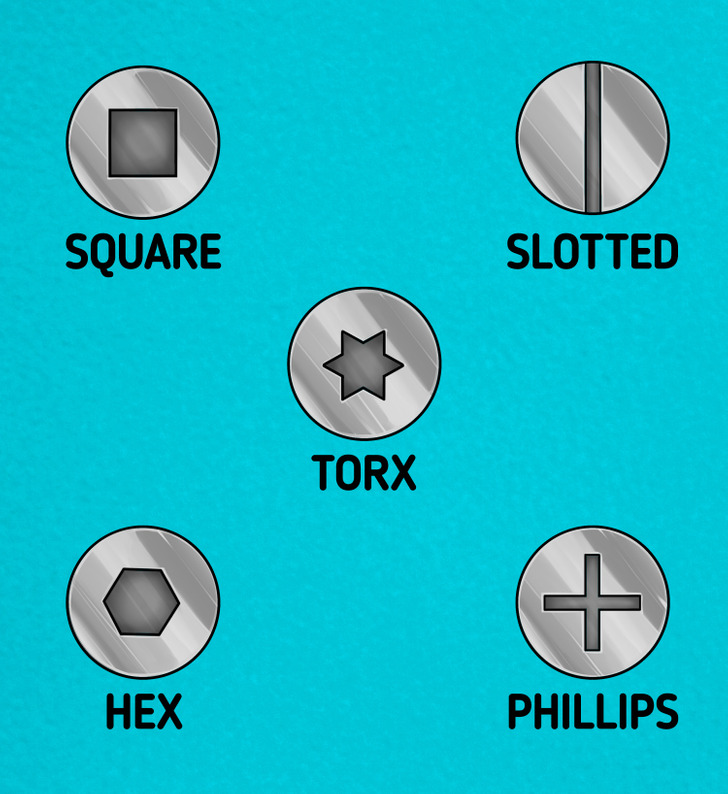

Common types of screw drives

In most cases, you will have at least some degree of variety when it comes to the screws that you can use, mainly due to the many types of drive recesses available. Certain screw drives owe their design to things such as stability during application and torque. You will need to use a different tool for each specific type of screw drive. These are some of the types of screw drives you’ll find:

- Slotted: Characterized by a single line across its head, slotted screws are the oldest type of screw available. Its simple shape lets you tighten or loosen it with household items like a coin or a knife, but they may prove difficult to stabilize during installation, which makes them unreliable when you’re working with power tools, as they tend to slip.

- Phillips: A more stable alternative thanks to the 4 contact points on its head, Phillips screws are also better suited for screwdrivers and power tools. Named after Henry F. Phillips, who improved on its cross-like drive recess, these screws were designed in such a way that a screwdriver will cam out once a certain amount of torque is needed to keep it turning, which prevents over-tightening.

- Hex: Commonly used for objects such as pre-made furniture, hex screws usually need to be tightened with an L-shaped hex key, also known as an Allen wrench — however, other compatible tools are also available. They possess a deeper recess, which makes it harder for the screw to become stripped.

- Square: Also known as Scrulox or Robertson, square screw drives have become a more popular option with time because their shape makes it so camming out or slipping will rarely happen.

- Torx: Also known for their effectiveness in preventing camming out, Torx screws are mainly notorious for to their 6-pointed star shape on the head. This shape allows for Torx screws to provide a great amount of torque during installation, which has increased their popularity.

1. Screws for wood

- Wood screws can be recognized by their partially threaded body. They’re made in many materials, but wood screws made of steel are fairly common. However, using wood screws can be a complex endeavor, as you’ll need to drill additional holes, such as a pilot hole, for the screw to be fastened properly.

- A more inexpensive alternative is the drywall screw, which also benefits from being easy to find in stores and not requiring you to drill pilot holes. However, they are thinner than regular wood screws, which makes them more brittle and increases the chances of them snapping, making them a less than ideal option for projects that need heavier work.

- If you need a strong screw, the best option is a multi-purpose screw. These are made of hardened steel and have self-drilling points, which eliminates the need to drill pilot holes. They might be more expensive, but they come with the added benefit of also being available in Torx and square drives.

- In case the screws will be exposed to corrosion, like with outdoor installations, you can use deck screws or stainless steel screws. The former is more sturdy, but the latter is more corrosion-resistant.

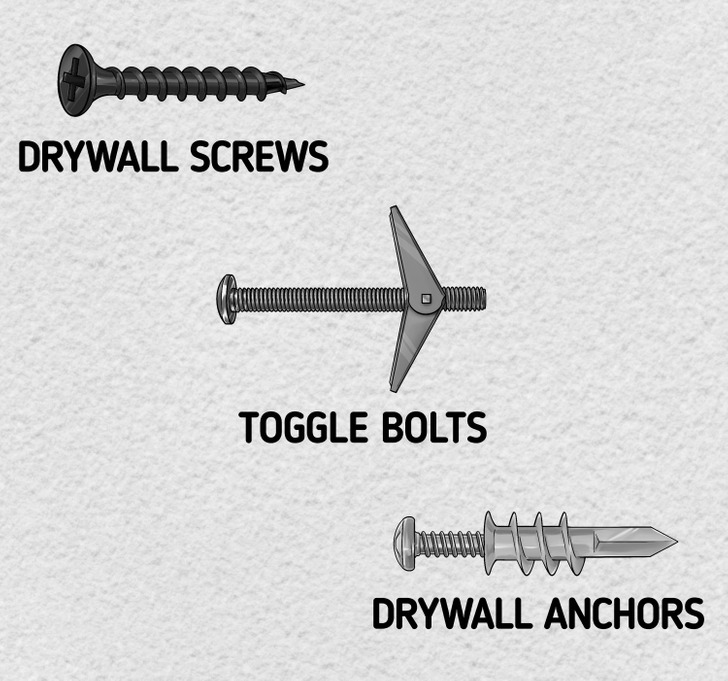

2. Screws for drywall

- Drywall screws are ideal for attaching drywall panels to metal studs or wood, given the fact that they usually countersink just below the surface of the drywall, which makes concealing them much easier. Their deeper threads and higher length also prevent the screws from loosening from the surface they were drilled into, and their sharpness and self-drilling tip will make drilling the screw very easy.

- In the case of drilling through drywall to hang something, it is recommended to use drywall anchor screws, preferably ones that are designed to hold the desired weight.

- Toggle bolts or butterfly anchors can be used as a fastener for hanging objects on not only drywall but also other hollow wall systems, such as plaster.

3. Screws for metal

- Screws that are made for metal surfaces are characterized by having longer threads that run along the entire body of the screw, as well as having more threads per square inch. Some screws that are made for metal are self-drilling, meaning that their point is shaped like a drill bit. This means that the screw will be able to go through metal and won’t require you to drill a pilot hole.

- In the case of working with sheet metal, sheet metal screws will be your best bet. They’re usually smaller in size, and they have a sharp point that will allow them to drive into metallic surfaces.

- Another common alternative is the machine screw. Often used to fasten metal parts in machinery and construction and commonly found in electronic devices, machine screws are known for being flat-tipped and smaller. However, they are also stronger than many other types of screws.

- Wood to metal screws do a great job at fastening both surfaces together. Their design includes wings that will ream out the wood as it is being drilled, which break off once the drill reaches the metal part.

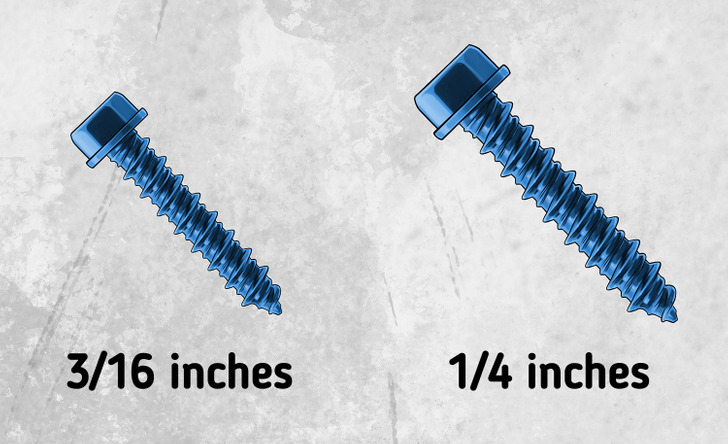

4. Screws for concrete

- Concrete screws are often blue-colored and come in 2 diameters: 3/16 inches and 1/4 inches. The former will suffice for most drilling needs inside your house, such as attaching hardware or screwing walls to concrete floors, but the latter may be necessary if the concrete is too hard.

- If the screw is spinning in place without it gripping the concrete, it’s likely that the material you’re installing the screw in is too soft. In such cases, it’s recommended to use longer 1/4-inch screws.

- Concrete screws can often be found with a hex head or a Phillips flat head. You will have an easier time screwing with a hex screw, but screws with a Phillips head come with the benefit of having a flat head that stays flush to the surface.

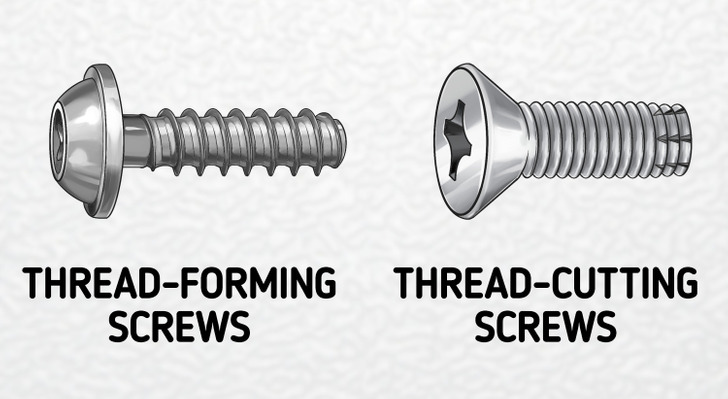

5. Screws for plastic

- Using any kind of screw-on plastic may lead to an excessive amount of stress being applied to the surface, which may lead the plastic to burst during the screwing process. It is recommended to use self-tapping screws for plastic, namely thread-forming or thread-cutting screws.

- Thread-forming screws are better suited for thermoplastics, such as ABS, polycarbonate, and polyethylene, which can be found in things such as toys, drinking bottles, and plastic grocery bags, respectively. These screws displace and reshape the material around the screw as a way to create internal threads for easier fastening.

- Thermoset plastics, which are characterized by the fact that they can’t be re-melted, will need thread-cutting screws instead. These feature cutting edges that remove part of the material to create internal threads. Some examples of materials that need thread-cutting screws are epoxy, silicone, and polyurethane.

CLICK to join a new online writing course given by the 5-Minute Crafts team!