How an Internal Combustion Engine Works

It’s hard to imagine the modern world without an internal combustion engine. It helps us get to work in the morning or travel the world comfortably. But despite the fact that these engines are very popular, very few people know how they work.

5-Minute Crafts would like to tell you about what an internal combustion engine is and how it works.

A simple definition of an internal combustion engine

An internal combustion engine (ICE) is a machine that converts fuel into mechanical energy. It belongs to heat engines, meaning it burns fuel to produce the energy necessary for work.

ICEs are used in airplanes, ships, railroad locomotives, and most automobiles, as well as lawnmowers, chain saws, air compressors, and so on.

An internal combustion engine is named as such because fuel ignites and burns inside it. ICEs are currently the most widely used energy-generating devices in the world.

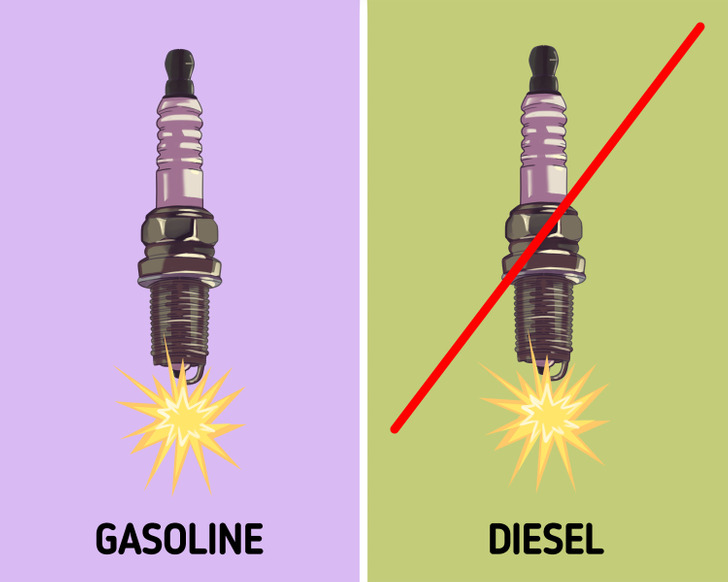

Gasoline and diesel ICEs

The most common internal combustion engines are gasoline and diesel.

They are basically the same. Both engines work thanks to fuel, air, and ignition.

And yet there is a difference between them.

- In a gasoline engine, fuel is mixed with air, then compressed by a piston inside the cylinder and ignited by a spark from a spark plug.

- In a diesel engine, the piston first compresses the air, and only then fuel is injected. The spark plug is not used here. The air is very hot when compressed, making the fuel ignite.

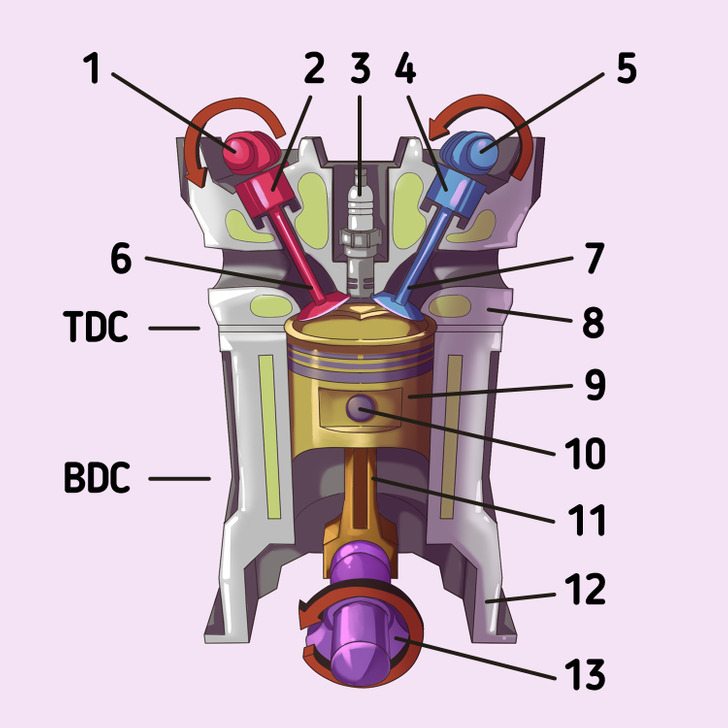

The parts of an internal combustion engine

The most common internal combustion engine is a 4-stroke gasoline engine.

It consists of the following components:

- Exhaust camshaft

- Exhaust valve bucket

- Spark plug

- Intake valve bucket

- Intake camshaft

- Exhaust valve

- Intake valve

- Cylinder head

- Piston

- Piston pin

- Connecting rod

- Engine block

- Crankshaft

- TDC — Top Dead Center

- BDC — Bottom Dead Center

Some components of an ICE are fixed:

- cylinder head

- cylinder block

Some components move:

- camshaft sprocket

- piston

- crankshaft

- connecting rod

- valve

How an ICE works

Above, we examined the components of a 1-cylinder internal combustion engine. In automobile engines, 4 to 8 cylinders are often used. There are cars with 16 cylinders. And reciprocating aircraft engines have as many as 28 of them. The more cylinders an engine has, the more powerful it is.

A cylinder is the power unit of an engine. Generally, engines with more cylinders produce more power, while those with fewer cylinders get better fuel economy.

A cylinder doesn’t always have 2 valves. To increase engine power, 4 valves per cylinder are often used.

In all internal combustion engines, fuel is burned internally. The combustion chamber consists of a cylinder in which a tightly fitting piston runs. It moves inside the cylinder from bottom dead center (BDC) to top dead center (TDC). The movement of the piston between these points is a stroke. The piston is attached to a connecting rod which is connected to the crankshaft. Through this, the up and down movements of the piston are converted into rotational movements.

The power of an ICE is obtained by burning a mixture of fuel and air in a small, enclosed space. When fuel burns in the air, hot gas is formed, the volume of which expands. It pushes the piston, which rotates the crankshaft. Using a car as an example, this motion is sent to the wheels that move the car through a system of gears in the powertrain.

4 strokes of an engine’s work

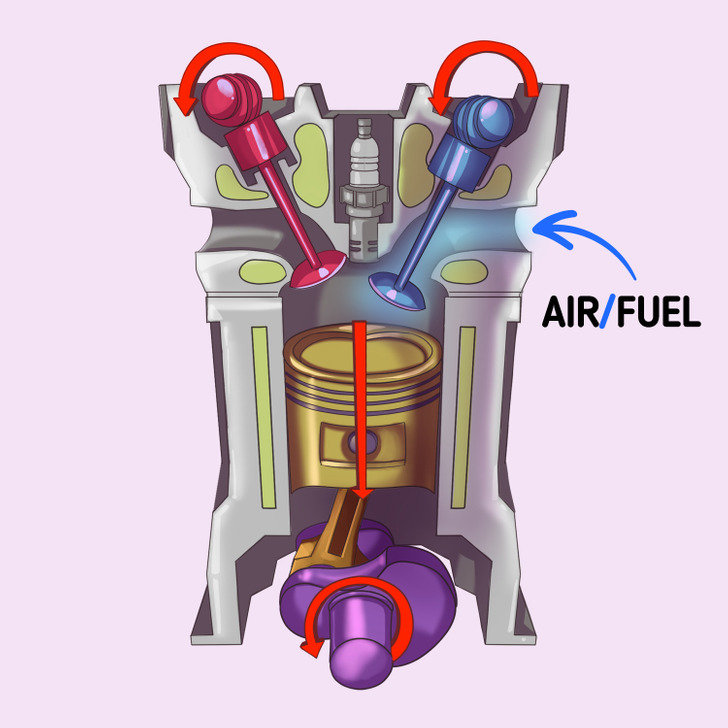

Intake

- At the beginning of the first stroke, the piston is close to TDC.

- The intake valve opens and the piston moves down to BDC. At this point, an air-fuel mixture is sucked into the cylinder, or just air, if we are talking about a diesel engine.

The intake stroke ends when the piston reaches BDC. During the first stroke, the engine consumes energy.

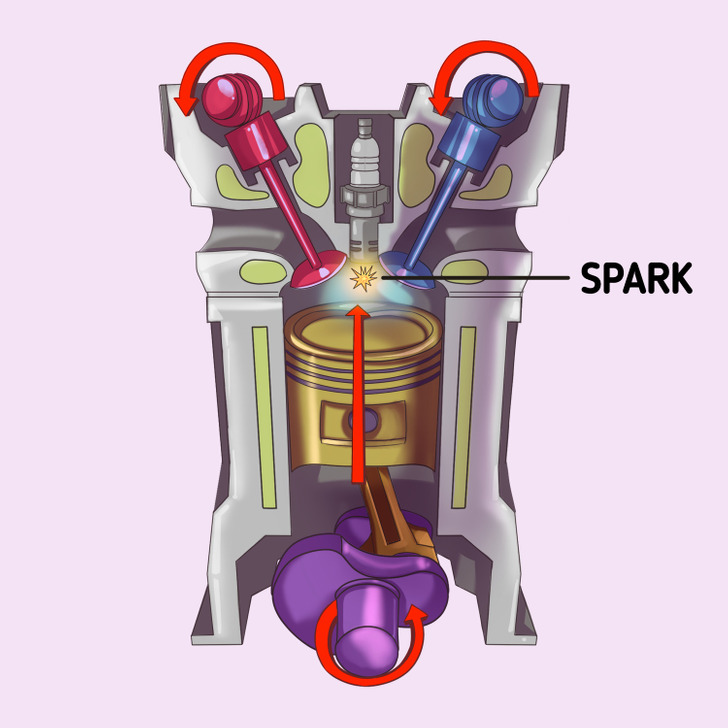

Compression

- At the beginning of the second stroke, the piston is close BDC.

- The intake and exhaust valves are closed during this stroke.

- The piston starts to move up to TDC. At this point, it compresses the mixture of air and fuel in gasoline engines or just air in diesel engines. Maximum pressure is reached when the piston is close to TDC. Around the same time, a spark is generated in a gasoline engine and fuel is injected in a diesel engine.

During the compression stroke, the engine still consumes energy — even more than in the intake stroke.

Power

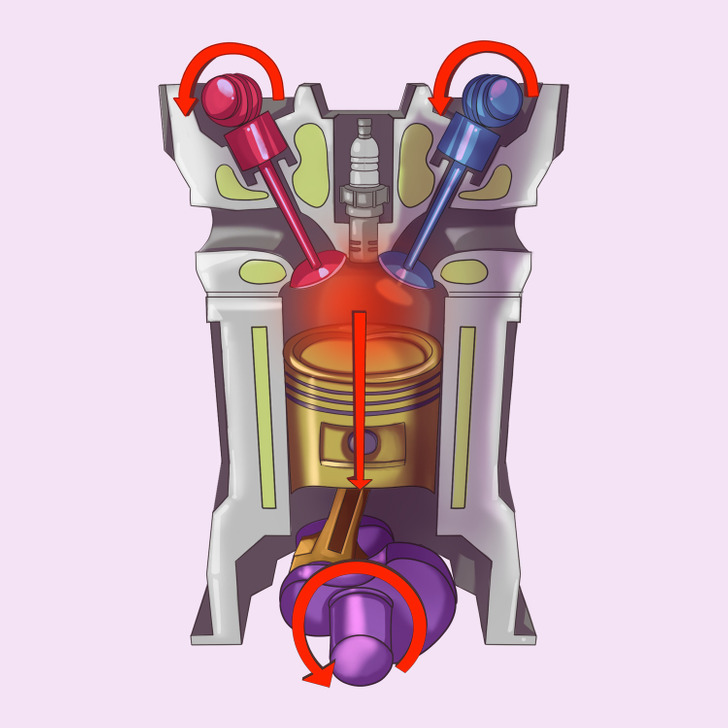

- At the beginning of the third stroke, the piston is at TDC.

- The intake and exhaust valves are closed.

- Combustion of the air-fuel mixture begins at the end of the compression stroke. This process results in a sharp increase in pressure inside the cylinder, which pushes the piston down to BDC.

At this moment the piston, through the connecting rod, causes the crankshaft to rotate. The force that is applied to the crankshaft is called torque.

During the power stroke, the engine produces energy.

Exhaust

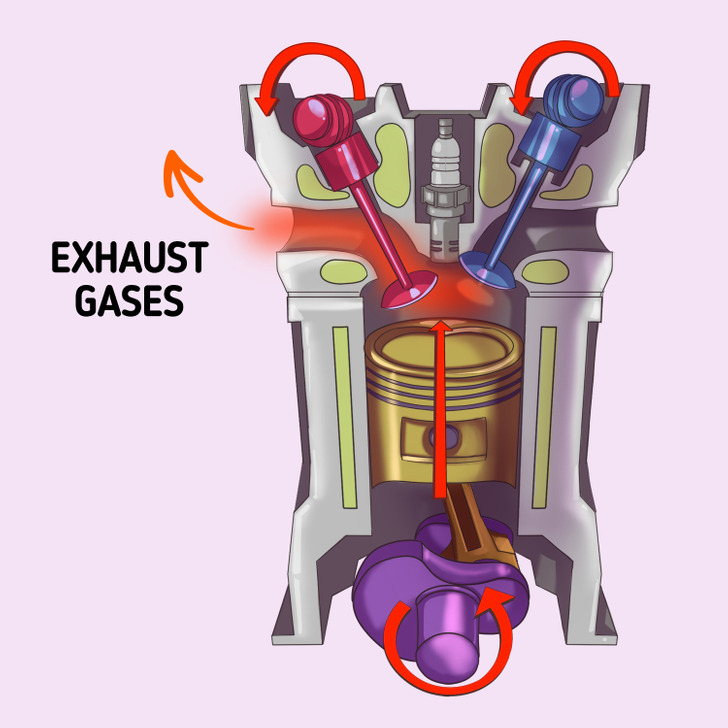

- At the beginning of the fourth stroke, the piston is at BDC, where it was pushed by the pressure that increased after the fuel combustion.

- During the exhaust stroke, the exhaust valve is open.

- The piston starts moving from BDC to TDC, pushing most of the exhaust gases out of the cylinder into the exhaust pipes.

During the exhaust stroke, the engine consumes energy again.

The internal combustion engine efficiency

Not all of the fuel received by the engine is converted into useful energy. Most of the energy is converted into heat, which is neutralized by the cooling system.

The efficiency of 4-stroke engines is 20–25%. Only this percentage of fuel energy is converted into mechanical energy. The rest goes into the cooling system and exhaust.

Diesel engines are more efficient. In large ones, efficiency reaches 42%. For automobile and truck engines though, the range is only 25 to 30%.

Brief history

The first commercial internal combustion engine was invented by engineer Jean Joseph Etienne Lenoir. In 1860, Lenoir mounted a gas-fired, single-cylinder internal combustion engine on a 3-wheeled carriage, and patented it.

The first internal combustion engine worked quite well but was too noisy and often overheated. It had to be cooled down with water. Besides, Lenoir’s invention couldn’t be called economical.

In 1863, the engineer introduced a 3-wheeled carriage that ran on gasoline. During the demonstration in Paris, it covered 7 miles in 3 hours. And although the carriage moved very slowly, it made a rather strong impression, because it moved powered not by a horse or a mule, but by an engine.

Lenoir’s engines were quite popular. About 500 of them were built in total.

In 1876, Nicolaus Otto invented an effective gas motor engine. It was the first 4-stroke internal combustion engine. The engine was immediately built into a motorcycle. The Otto Cycle Engine used the principle of intake, compression, power, and exhaust. This is how most modern internal combustion engines in cars or motorcycles operate.

In 1885, Karl Benz built the first car powered by an internal combustion engine that ran on gasoline, and he patented it in 1886. Benz based the development of his engine on Otto’s work, while Otto used the Lenoir gas engine as a template.