What Glass Is Made Of

5-Minute Crafts is going to tell you what glass is made of, how it’s produced, and whether it can be formed naturally.

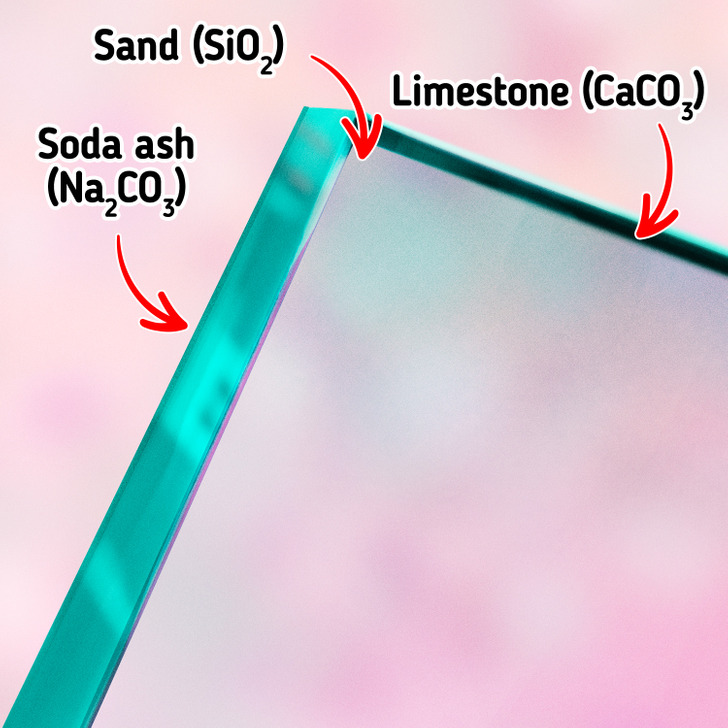

What glass is made of

Glass is normally made of 3 ingredients: sand, limestone, and soda ash.

Sand, or silicon dioxide, is the most popular base for glass. It consists of very small crystals. If you melt it at very high temperatures, it will become liquid. After that, it becomes solid again, but in a different form — as a thin transparent peice of glass.

The glass made from silicon is called silicate. It’s not the only base for glass people use. The following ingredients might also be used instead:

- Sodium carbonate is a good kind of glass to use for windows and dishes.

- Borosilicate glass has low coefficients of thermal expansion, which is good for lab equipment and everyday dishes, along with car lights.

- Lead glass is very shiny with a lot of refraction and beautiful light. This is why it’s often used to produce dishes, especially colored glass.

- Aluminosilicate glass has great thermal resistance and durability, so it’s often used to produce fiberglass, glass-reinforced plastics, stove-top cookware, and halogen bulb glass.

As we said before, aside from sand, limestone and soda ash are used in glass production. The soda is used to speed up the melting process, and limestone is needed to make the product more durable. Sometimes, limestone is replaced with dolomite or used together with it because these 2 ingredients have similar qualities.

How glass is made

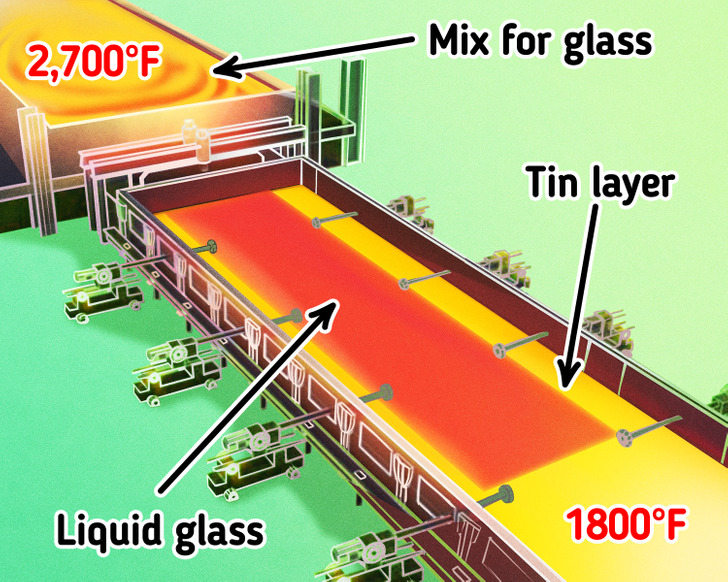

Let’s take a look at how glass is made with the example of float glass, which is used for windows, doors, furniture, car windows, mirrors, and other products. Its production usually includes at least 4 steps:

- Melting: A mix of sand, soda, limestone, and/or dolomite is put into a furnace and melted at around 2,700°F. Around 20% glass cullet may be added to the mix. After lots of stirring, gas bubbles emerge and are removed while the liquid glass is moving. After that, a molten glass ribbon floats atop a bath of liquid tin. This stage takes up to 50 hours.

- Shaping: Liquid glass goes down the canal and spreads on the surface of a thin layer of liquid tin at around 1,800°F. At this stage, the glass is very viscous, so it doesn’t mix with the tin and forms a flat glass ribbon. The thickness is controlled by how fast the glass spreads around the tin, and the width is adjusted by the machine rollers on the sides. After that, the glass ribbon leaves the float chamber at around 1,100°F.

- Cooling: The glass ribbon keeps going and slowly solidifies in the annealing chamber. The temperature here is carefully controlled and is gradually reduced to around 480°F. When the ribbon leaves the chamber, it cools down and solidifies because of the cold air. Now, the glass can be tested for quality and, if it’s good, can be cut into sheets.

- Coating: After cutting, different kinds of coating may be applied to the glass to improve its properties, from solar control to improved insulation and anti-reflection properties.

Natural glass

Glass may form naturally from volcanic magma. For example, obsidian is a volcanic glass with a high concentration of silicon dioxide. It forms through quick lava cooling erupted from a volcano.

Another example is impactites, which are rocks formed or modified by 1 or several impacts of a meteorite. Examples are moldavite (seen in Central and Eastern Europe) and Libyan desert glass (found in the Eastern Sahara, deserts of Easter Libya, and Western Egypt).